A Cloud-Edge Collaborative Solution for Intelligent Oil & Gas Production and Operation

Introduction

With the reduction of oil and gas reserves and the intensification of global market competition, oil and gas production enterprises are seeking digital transformation to optimize resources and enhance production efficiency. EMQ provides a one-stop cloud-edge collaborative IoT solution that addresses common industry challenges such as data collection, system construction and maintenance. It consolidates data generated by different systems onto one platform, facilitating more precise management and reduced costs.

Based on historical cases, EMQ’s solution can help oil and gas companies save more than 25% in annual collection system maintenance costs and over 40% in data point access costs.

Building Intelligent Oil&Gas System with EMQ

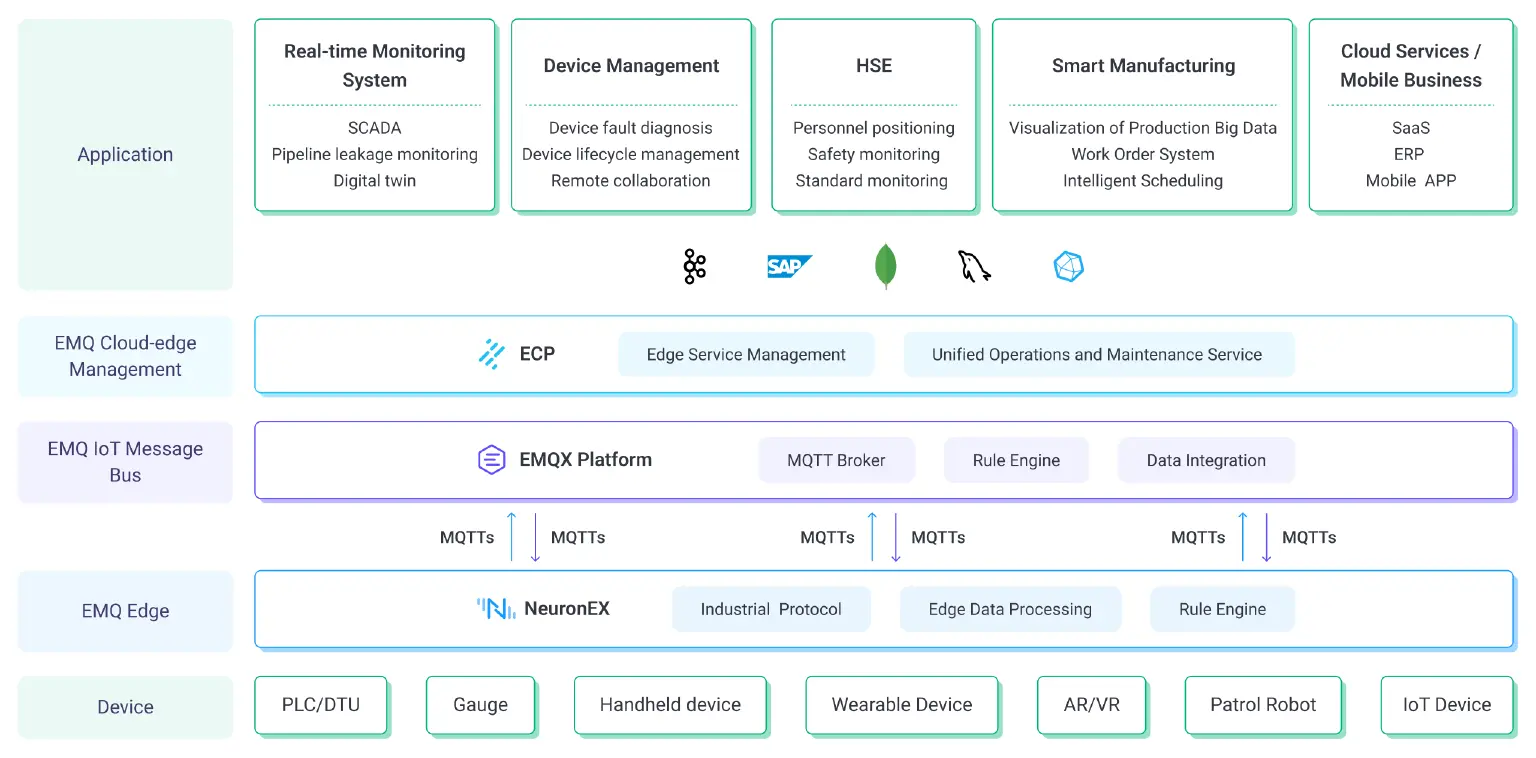

EMQ provides a comprehensive cloud-edge collaborative architecture encompassing industrial data acquisition, edge computing, data integration, and remote operational management. This solution can be used by oil and gas companies for real-time monitoring, equipment management, HSE(Health, Safety, Environment) management, smart production, and intelligent applications. With EMQ, enterprises can achieve greater efficiency and better control over their operations.

Real-time Industrial Data Acquisition

The industrial protocol gateway software, NeuronEX, supports various bus and industrial protocols, such as Modbus, OPC UA, Siemens, ABB, Mitsubishi, and Schneider. It collects real-time data from devices in production sites and then converts them into standard MQTT protocol messages, with data points adhering to unified formatting standards and millisecond-level timestamps. NeuronEX also caches data offline to ensure the integrity of historical data during network interruptions.

NeuronEX’s rule engine enables real-time computation and analysis, message standardization, data filtering, intelligent alarms, business routing, data persistence, and more at the edge. This allows oil and gas producers to preprocess data and process event logic at the edge.

NeuronEX’s HTTP PULL feature allows the perception of the configuration status and operating data of intelligent IT devices at the production field.

Moreover, NeuronEX can integrate AI for intelligent video monitoring, safety management, equipment maintenance, fault prediction, inspection, and safety monitoring through real-time processing of IoT data and video streams.

Enterprise-Grade IoT Message Bus

EMQX Enterprise deployed in the plant-level information center or group cloud provides a unified platform for oil and gas production data on private networks or the internet. This achieves high availability, high concurrency, and low-latency data transmission, analysis, processing, and integration. EMQX Enterprise MQTT platform can simultaneously handle connections from over a million IoT devices and process over a hundred thousand data interactions per second. It is highly suitable for the oil and gas production environment.

What You Can Achieve with EMQ

Comprehensive Perception and Centralized Management

EMQ’s solution facilitates data collection and management from intricate production equipment in oil and gas production, as well as safety and monitoring devices in the field. The cloud-edge collaborative architecture and data aggregation capabilities can address the challenge of centralizing the management of data from originally independent and scattered systems.

Cost Reduction and Efficiency Improvement

The solution simplifies the complex maintenance tasks involved in oil and gas production through the unified intelligent management of equipment access, inspections, configurations, upgrades, updates, and alarm handling. This significantly reduces costs caused by manual operation and improves efficiency.

Scalability and Flexibility for Future Innovation

The solution provides expandable interfaces to facilitate the integration of new systems and technologies into the business platform. At the edge, it supports the integration of algorithms in MATLAB, C, C++, Python, GO, and AI, promoting innovative development in edge intelligence.

Standardized configurations speed up IoT platform construction, making it easier to replicant and scale as the business grows.

The entire solution can be deployed through containerization, supporting cloud-native architecture to achieve unified container orchestration and management. This promotes the integration and innovation of smart oil and gas systems with cloud-native technologies.

Related Products

EMQX Enterprise

EMQX Enterprise is a powerful enterprise-level IoT messaging platform designed for large-scale deployments and high reliability in IoT applications. The following capabilities of EMQX Enterprise can benefit the industry:

- High Reliability and Scalability: EMQX Enterprise adopts a distributed architecture with high availability and scalability to handle large-scale concurrent message transmission. It supports horizontal scaling to accommodate the growing number of IoT devices and data traffic, ensuring system stability.

- Rich Protocol Support: EMQX Enterprise supports multiple messaging protocols besides the MQTT protocol. It allows developers to extend to support all kinds of private protocols for their application needs.

- Data Integration: EMQX Enterprise seamlessly integrates with various data storage services, message queues, cloud platforms, and applications. It can connect with cloud services, enabling remote data transmission and cloud-based analysis.

- Security and Authentication: EMQX Enterprise provides robust security features, including TLS/SSL encrypted transmission, client authentication, and access control. It supports various authentication methods such as username/password, X.509 certificates, and OAuth, ensuring the security of IoT communication.

- Rule Engine and Data Processing: EMQX Enterprise has a flexible rule engine for real-time data processing and forwarding based on device data. It supports operations such as data filtering, transformation, aggregation, and persistence, helping users analyze and make decisions based on their business needs.

- Visual Monitoring and Management: EMQX Enterprise provides an intuitive visual monitoring and management interface, allowing users to monitor IoT devices and message transmission in real-time. Users can view connection status, message traffic, and other metrics and perform device management, troubleshooting, and system configuration operations.

NeuronEX

NeuronEX is software tailored for the industrial sector, focusing on equipment data collection and edge intelligent analysis. It is primarily deployed in industrial settings, facilitating industrial equipment communication, industrial bus protocol acquisition, industrial system data integration, edge-level data filtering and analysis, AI algorithm integration, and integration with IIOT platforms. It offers the following features:

- Diverse Connectivity: NeuronEX provides multi-protocol access capability, supporting simultaneous access to dozens of industrial protocols such as Modbus, OPC UA, Ethernet/IP, BACnet, Siemens, Mitsubishi, and more. It enables integration with multiple data sources from systems like MES and WMS within the enterprise. NeuronEX also supports bidirectional data flow, allowing both data acquisition and control command issuance to devices.

- Deploy anywhere: Neuron has very low memory footprints and is suitable for running on low-profile architecture devices like x86, ARM, RISC-V, etc. It also supports docker-like containerized deployment, running with other co-located containers in Kubernetes environments.

- Data Processing: NeuronEX incorporates 100+ built-in functions, supporting data filtering, data manipulation, device control, and data persistence, storing data in a time-series database.

- Algorithm Integration: NeuronEX supports the integration of algorithms written in languages such as C, Python, and Go. It facilitates real-time inference of industrial mechanism models, machine learning, and deep learning models at the edge, enabling alerts and intelligent decision-making.

- Edge to Cloud: Through protocols like MQTT and SparkplugB, NeuronEX aggregates and pushes industrial data to cloud platforms. The bidirectional data flow between NeuronEX and the cloud platform establishes cloud-edge data coordination and control synergy, leveraging the platform's big data storage and analysis capabilities to amplify the value of NeuronEX usage.