Challenge

Stable data transmission in complex network environments

Engineering machineries achieve equipment data upload and message downlink through the operator network. The onsite work environment can be complex, with varying network conditions. Hence, there is a need to ensure the secure and stable transmission of data in weak networks and other adverse environments.

Application layout under high throughput

With the increase in the number of equipment, the Internet of Things technology would need to achieve project overview, remote control, fault diagnosis, positioning tracking, alarm statistics and other visualized controls under high throughput data. This requires robust data access and storage architecture.

Bottleneck of massive data distribution

With the rapid increase in business volume, bottlenecks would occur in the process of sending massive downlink data, resulting in data delays, packet loss, the inability to complete the remote control of equipment, and other scenario applications.

Solution

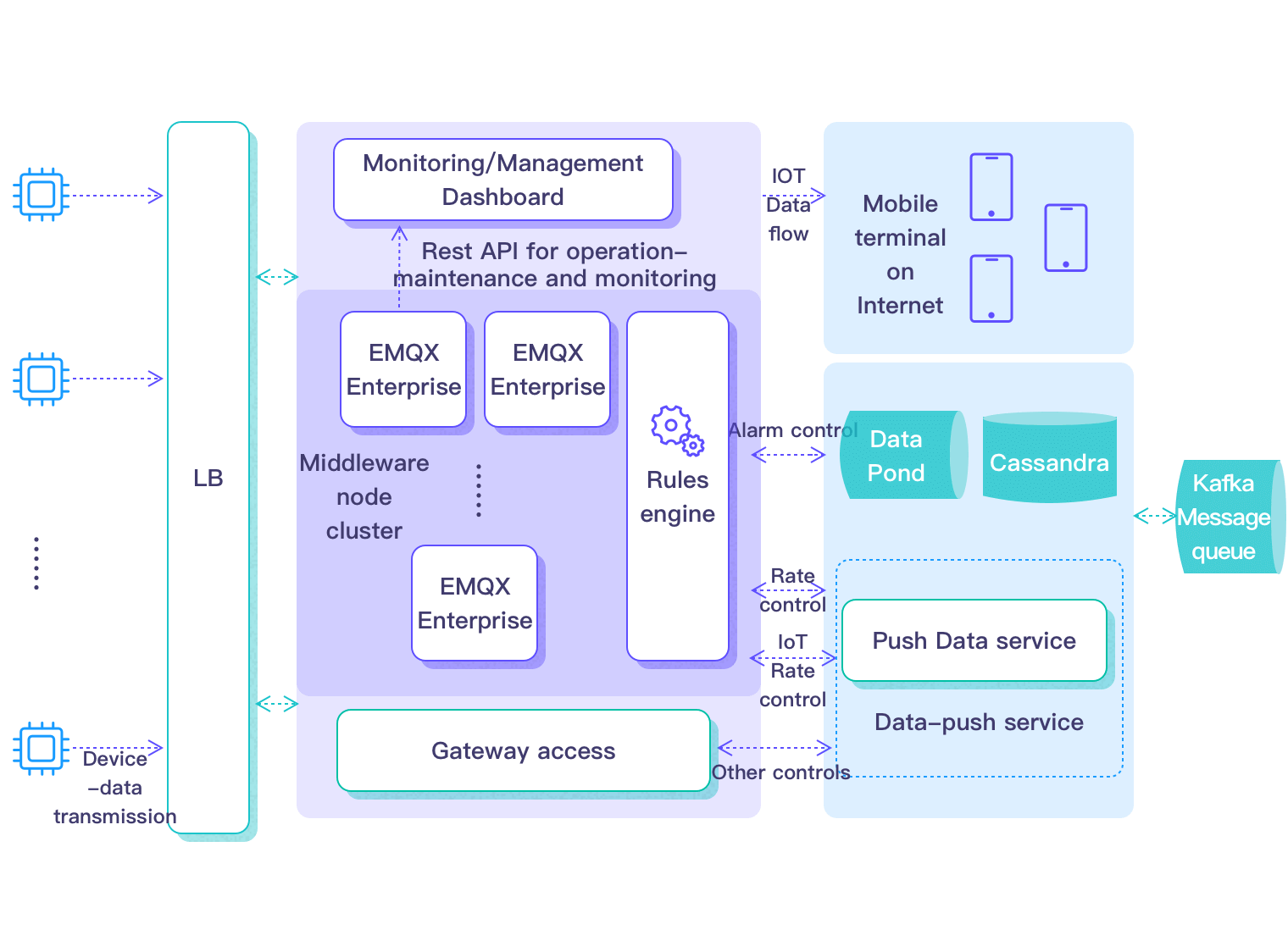

The EMQ engineering machinery IoT solution adopts the cloud-native distributed MQTT message server EMQX for unified access to the high-frequency collection of massive data, at a million messages per second concurrency. This ensures the real-time, complete and secure data transmission in environments of poor network quality and transmission bandwidth constraints.

The flexible and scalable cluster mode can expand the cluster scale without stopping. A single cluster can handle millions of TPS message concurrency, providing good scalability and stability of the data architecture layer to meet the business growth demand, despite the increase in equipment access.

The powerful rules engine can realize one-click data persistence, and solve problems related to direct storage, when data is not delivered. By adding a buffer parameter setting, the data delivery rate is controlled through the SQL configuration alert in the rules engine. In addition, with the rules engine, a series of events, such as the online and offline status of devices, and packet loss, can trigger the complete delivery of messages, solving the problem of webhook inefficiency. In addition, different zones can be used to achieve different authentication methods for internal and external networks.

In terms of operation and maintenance management, the EMQ solution provides group and registration management, subscription and publishing authority management, and online and offline device management, and realizes message pushing, making system management easier and more convenient.

Results

- Through the EMQ IoT infrastructure software, the concurrent access to data of large-scale engineering machinery and equipment can be achieved, ensuring the real-time, secure and stable processing of vehicle-end data, message transmissions, and data storage.

- Based on the robust data transmission layer provided by EMQ for engineering machinery and equipment networking, engineering machinery and equipment fault prediction and health management, remote control, real-time alarm, product maintenance cost reduction, product design optimization and R&D can be realized. Thus ultimately leading to the whole life cycle management and service extension of products.